Custom tooling is a personalized solution for manufacturers looking to improve their production processes. Manufacturers who go the custom route can have tools created that meet their required specifications and standards. Despite the increased cost of custom design tooling, manufacturers can see an improved return on investment (ROI) when using custom tools.

Custom tooling is a personalized solution for manufacturers looking to improve their production processes. Manufacturers who go the custom route can have tools created that meet their required specifications and standards. Despite the increased cost of custom design tooling, manufacturers can see an improved return on investment (ROI) when using custom tools.

Switching to custom tooling can result in significant time and cost savings for manufacturers, enabling an increase in productivity within machining operations. Manufacturers looking for creative ways to improve production within current operational limitations should explore the versatility of custom tooling solutions.

Custom Tooling Considerations

Custom tooling provides manufacturers with flexibility through time savings — they don’t have to settle for a standard tool solution. They can have a customized tooling solution that not only meets their needs, but also helps improve their production process. However, there are some considerations when it comes to custom design tooling.

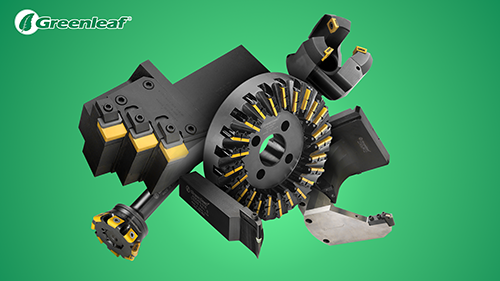

“Customized tooling solutions can simplify operations for manufacturers,” explains Martin Dillaman, Global Manager of Engineering/Applications at Greenleaf Corporation. “It can be as basic as making a milling cutter at a larger size that allows them to produce parts in one pass instead of two. Or it could be creating a complete special form with special insert designs coupled with a special tooling design that allows manufacturers to shorten their overall process.”

Tooling needs are different for each individual manufacturer, and when a catalog tool can’t meet the requirements, that’s when customization comes into the picture.

“If all tooling requirements are taken into consideration to design one integral tool, that enables manufactures to decrease tool changes and reduce cycle times,” says Dillaman. “Creating custom tooling comes down to saving time and offering the best quality part. That’s always a focus in our tooling solutions.”

The Benefits of Custom Tooling Solutions

Creating customized tooling solutions, especially ones that combine multiple operations into one tool, leads to better production outcomes for manufacturers. Time savings and improved quality are two of the biggest benefits of using custom tooling.

“Wherever a manufacturer can cut out an operation or reduce the tool changes for the operation, that adds to the total productivity they can achieve,” Dillaman explains. Manufacturers who have high volume production runs often benefit the most from custom tooling and see the biggest savings, especially in total production time.

“Wherever a manufacturer can cut out an operation or reduce the tool changes for the operation, that adds to the total productivity they can achieve,” Dillaman explains. Manufacturers who have high volume production runs often benefit the most from custom tooling and see the biggest savings, especially in total production time.

Total volume of parts to produce plays into the equation for determining if custom tools are beneficial. If a manufacturer is producing a large volume of parts and can save several minutes per part with custom tooling, they can improve overall productivity and justify the increased costs of custom tooling versus standard tools.

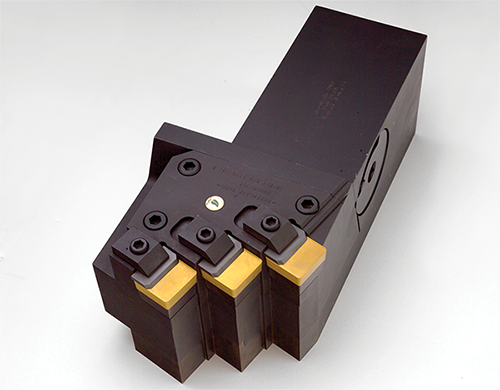

Dillaman expands on this with a real-life example: “One project I worked on involved developing a special toolholder and insert that allowed for multiple grooves to be cut in a single pass on the multi-spindle machine. This solution ended up saving 80 seconds per part, which equated to over 1000 hours saved annually for one product line.”

This example highlights how having the right custom tools can help large volume manufacturers increase productivity by significantly reducing cycle time. That huge time savings makes a significant difference in the total cost to manufacturer a part. Producing parts at a much higher rate helps reduce material overhead costs and manufacturing costs, further improving manufacturers’ ROI when they switch to custom tooling.

As for quality, custom tooling often makes a difference to the surface finish and overall quality of a part. Tool changes between multiple tools due to part geometry can sometimes cause mismatches and poor surface quality in a finished part. Using one custom tool enables manufacturers to avoid tooling changes and ensure the tool pressure is equal and balanced for a high-quality surface finish.

Overcoming Barriers to Acquiring Custom Tooling

Custom tooling offers significant benefits to manufacturers, but there are still some barriers for companies looking for custom solutions.

“One issue we occasionally see is that a manufacturer does not see the overall value of the tools and the reason for the higher price point,” Dillaman explains. “Producing specialized tools requires more engineering time and a more extensive manufacturing process.”

Though it is a higher price point, the value of custom tooling comes from the time and cost savings realized by manufacturers. The right custom tool can turn a four-operation process into one operation, resulting in a significant increase in productivity for that process.

“There are situations that almost necessitate the need for specialized tooling. It makes work easier for programmers, operators, and machinists to have those custom solutions instead of having to fight with a standard tool and try to manipulate it into a form that’s not easily achievable,” says Dillaman.

Getting Started with Custom Tooling

When considering custom tooling it’s important to know the benefits, but there’s also more to the process than just designing a specialized tool. Sometimes it can involve redesigning current processes or even creating new ones.

When considering custom tooling it’s important to know the benefits, but there’s also more to the process than just designing a specialized tool. Sometimes it can involve redesigning current processes or even creating new ones.

“Manufacturers looking into custom tooling must understand their constraints. Maybe they need more capacity but can’t buy new equipment. Customization can help, but it requires some innovative, outside-of-the-box thinking,” describes Dillaman.

To get the most out of a custom tooling solution, manufacturers must understand the issues within their production operations. Will it help to change to a different tool grade? Does the process need to be revamped? Would a different style of tooling work better?

“Customization isn’t always the answer, but when certain features and forms can’t be achieved with standard tooling, then custom is probably the best solution,” Dillaman says. “Manufacturers can achieve a lot more and save money in the long run with custom tooling.”

If you’re a manufacturer looking to improve your production process and interested in how custom design tooling can help, reach out to Greenleaf Corporation, a company focused on collaborating with their manufacturing customers to find the best solution. And if you want to explore more manufacturing technologies that can help you increase productivity, look into attending SOUTHTEC 2025.

Biography

Biography

Martin Dillaman, Greenleaf Corporation

Global Manager, Engineering/Applications

Project Manager

Martin Dillaman started with Greenleaf Corporation in 2018 as senior applications engineer. Prior to Greenleaf he worked as a machinist, process engineer, and engineering supervisor for a manufacturer producing products for the automotive, mining, and appliance industries. He currently manages the teams that design and develop tooling solutions and provide technical support for the application of all tooling.